BK Shaft Kiln Last generation

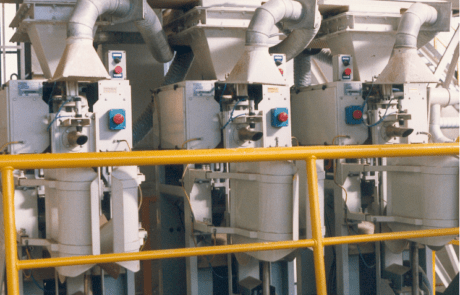

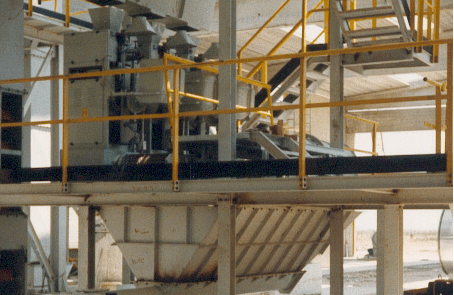

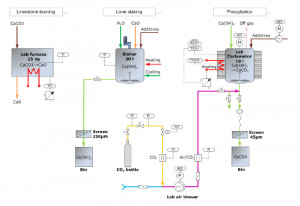

The BK kiln is equipped with external combustion chambers at two levels. A internal cylinder creates an annular zone through which the material passes.

The combustion gas is recirculated in the empty central cylinder and by controlling its temperature it is possible to produce different qualities of lime.

Fully automatic operation fine control of combustion system, have improved the quality of the performance of the kiln.

Technical Data

CAPACITY FROM: 300 tpd to 800 tpd

MATERIAL: Limestone and Dolomitic limestone

LIMESTONE SIZE: from 30 mm to 120 mm with ratio min/max size 1:2

FUELS: Any type of fuel can be used

FUEL CONSUMPTION: < 950 kcal/kg of lime

ELECTRIC POWER CONSUMPTION: < 35 kWh/Ton of lime

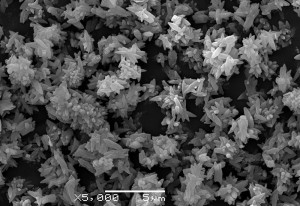

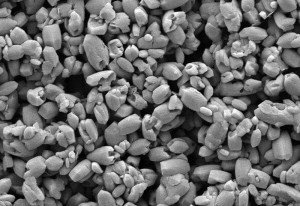

LIME QUALITY: Soft burnt lime (T60 < 3 minutes) to Hard burnt lime (T60 > 6 minutes)

RESIDUAL CO2 IN THE LIME: < 1%